They are designed to maximize strength considering typical machine shop capability and machine practice.Ĭlass 3 threads are used for closer tolerances.Ĭlass 4 thread fit is even tighter than a Class 3.Ĭlass 5 fit is not a loose thread. This system is analogous to the fits used with assembled parts.Ĭlass 1 threads are loosely fitting threads intended for ease of assembly or use in a dirty environment.Ĭlass 2 threads are the most common. Most (but certainly not all) threaded items are made to a classification standard called the Unified Screw Thread Standard Series. Industrial Press Inc.A classification system exists for ease of manufacture and interchangeability of fabricated threaded items.

#1.2512 2b thread form tap plus

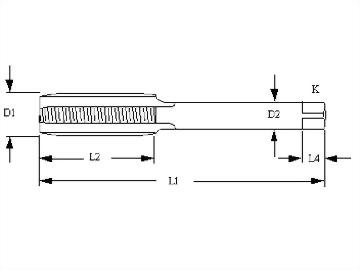

Maximum minor diameter plus ¼ minor diameter toleranceįor more detailed information on the calculation method and exceptions, FED-STD-H28/2B-1991 standard Maximum minor diameter (minimum minor diameter plus tolerance) Minimum minor diameter plus ¾ minor diameter tolerance Minimum minor diameter plus ¼ minor diameter tolerance Minimum minor diameter plus ½ minor diameter tolerance For long length of engagement, the hole diameter can be increased to have less risk of tap breakage.Īccording to this logic, the following recommendations were given in FED-STD-H28/2B-1991: For short length of engagement, the hole diameter shall be minimized to have The hole diameter required before tapping depends on the length of engagement. NoĬhips are produced during thread forming. Threads forming: A process to form threads by displacing the material to form the thread shape. Most commonly used class is 2 and thisĬlass is designed for general use. Interchangeability and manufacturability. Thread class: A classification system to classify the threads for Taps, thread forming taps, pulley taps, nut taps, and pipe taps.ĭiameter of hole before the tapping operation of the hole. Different type of taps exist such as straightįluted taps, spiral pointed taps, spiral pointed only taps, spiral fluted taps, fast spiral fluted Tap: A mechanical tool used to make a standard thread through a hole. Pitches than UNF are needed (Ex: Short engagement length). Pitch, or where finer adjustment is needed. Is short, where a smaller lead angle is desired, where the wall thickness demands a fine It is also used where the length of engagement

#1.2512 2b thread form tap series

The Fine series is suitable when the resistance to stripping of both externalĪnd mating internal threads equals or exceeds the tensile load carrying capacity of theĮxternally threaded member. Threads of this Fine Series have greater tensile stress area than comparable sizes of the Coarse series. Resistance against stripping (internal threads).

Is used in materials with low tensile strength which makes threads more Most commonly used type for general engineering applications.

Thread is intended for general purpose fastening operations. Thread interchangeability among these three nations. Mean values given in page 897 of Machinery's Handbook.ĭrill bit: A cutting tool used in drilling machines to drill a hole.įorm used by the United Kingdom, Canada, and the United States to obtain screw Note 3: Value is obtained by linear interpolation/extrapolation of Note 2: Equals drill size decimal equivalent plus expected amount of Parameters table, the effect of drill oversize will be taken into account in tap drill bit selection. Note 1: If the "Include Oversize" checkbox is ticked in Input Size of the internal thread’s minor diameter shown in the tables included in ASME B1.1-2003.Įxpected Hole Size (Including oversize) 2 Users select a drill bit size that will result in a hole size that lies between the maximum and minimum Past for threaded products users to determine tap drill size selection. Past changes in the thread form designation of the “basic” thread height from 0.750H to 0.625HĬonfused the calculation of percent of thread engagement. For length of engagement, options are L ≤ 0.33D, 0.33D ≤ L ≤ 0.67D, 0.67D ≤ L ≤ 1.5D, 1.5D ≤ L ≤ 3.0D.įollowing paragraph from ASME B1.1 has been taken into consideration while developing this tap drill size calculator.Īll references to percent of thread engagement have been eliminated from ASME B1.1-2003. For general use, select 1B & 2B thread class.

0 kommentar(er)

0 kommentar(er)